Rollable Ribbon’s Most Impressive Features

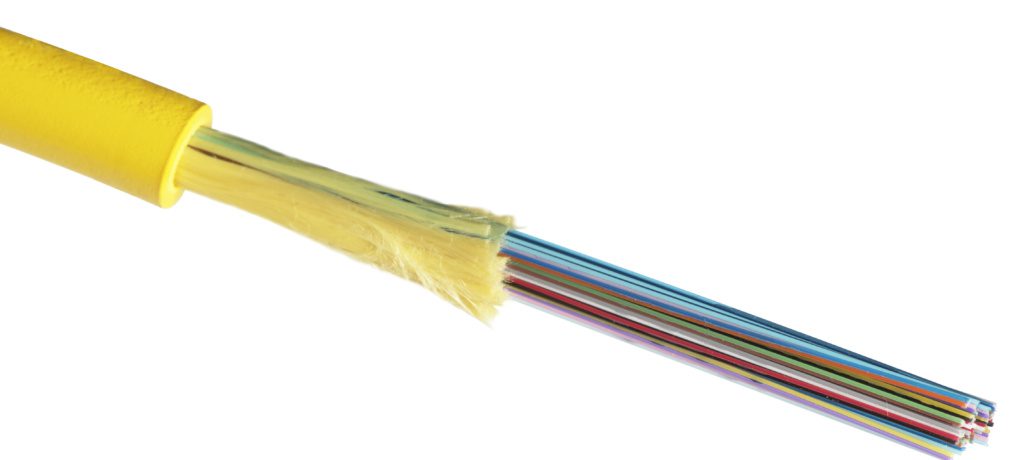

Leave a CommentMark Boxer, OFS Technical Manager, reveals what makes Rollable Ribbon so special. To form these ribbons, fibers are partially bonded to each other at intermittent points. This design not only enables mass fusion ribbon splicing but allows for easier individual fiber breakout than flat ribbons. The preferential bending plane of the rollable ribbons facilitates rolling and routing in smaller closures and splice trays, similar to individual fibers.

Learn more about Rollable Ribbon here.

Transcript:

Hi. I’m Mark Boxer with OFS. Today I’d like to talk about Rollable Ribbon and if you haven’t seen it before, it is this stuff, so it’s pretty neat. It collapses upon itself when it’s rolled into a tight cylinder so you can kind of collapse it.

And then you can also easily separate it out to pull out an individual fiber. So, I’ll do that and get a little bit closer. So you can see that and then it just snaps back into place so you can slice it again. So, it splices like a ribbon. It can be rolled very, very tightly, providing the ability of tight fiber density in a very, very small package.

So, you compare this to a flat ribbon. This is a flat ribbon and so there is no there is no moving of this or no rolling this without breaking the ribbon. So why this is important really comes back to geometry. So, this is an 864 fiber central to flat ribbon cable. So, if you look at it, you can see that there is a lot of space in between the flat ribbons and the tube.

And that’s because we’ve got ribbons that are fundamentally rectangles. And the cable is fundamentally a circle. When you have a circle and a rectangle, then it those don’t fit that efficiently. If you look at a rollable version of this cable with 864 fibers, you can see here there’s not very much space between the fibers and the tube.

And let me go ahead and put both of these side by side. And you can see that this is the flat ribbon 864. This is the rollable 864. Now there’s a significant difference in size between the two.

Rollable Ribbon was dreamed up in Japan back in the 2000’s and went through a development path that was actually similar to the SC Connector that happened in the early 1990s.

And what I mean by that is that NTT in Japan farmed out the concept to various companies who ultimately brought it to market. For the case of Rollable Ribbon OFS parent company, Furukawa was one of those companies that introduced Rollable Ribbon and so we brought it back to brought it to market during the middle part of the 2010’s.

So there are so many benefits to Rollable Ribbon. You know, we see it in a lot of different environments, and I call this the buffet of benefits using Rollable Ribbon. It’s small. The ribbons themselves are very small so they can be rolled. That means that cables can be much smaller and lighter for a given size.

That can gives the ability to fit more fiber into smaller ducts. It can mean smaller hand holds more cable on a real for longer lengths or fewer slice points. And then for aerial installations also since everything’s smaller, also less weight on the pole, less amount of ice to build up. Smaller in general typically makes things easier. Some customers like it because it can be placed in thinner slice trays enabling more trays and a closure or a smaller closure for a given fiber count.

All of these cables are gel free, so they’re easier to prepare for slicing. And of course, these are ribbon. So there can be mass fusion spliced 12 at a time. The initial installations were primarily used to connect data centers together because data centers use very high fiber count cables, you know, think of 1728s, 3456s.

But what I’m really excited about is the concept of using rollable ribbons in lower fiber count networks. Including fiber to the home, backbone, and distribution networks. For those applications, we have typically used, lose tube cables in the past because it’s easier to pull out an individual fiber to connect a subscriber. But now with Rollable Ribbon, it’s easier to pick out an individual fiber versus a loose tube. The ribbons or clearly marked, the fiber color is always going to be in the same place. You just basically pick out whatever you need.

So now the cables can be smaller, they can be easier to work with in the field. If you compare these so these 288 fiber count cables. The first is a loose tube. It’s actually pretty big. And this is a flat ribbon cable 288.

So now look at the rollable – and so we’ve got a couple of different versions of this but actually the larger rollable you can see that even the larger rollable is much smaller than either the loose tube or the flat ribbon.

All of these cables are GR20 rated. So you have the same rugged, crush, impact, and tinsel performance that we’ve come to rely on for decades. So give Rollable Ribbon some thoughts for your network. Now you can get the benefits of ribbon slicing when you can use it. Or also single fiber access. You can do either one, whenever or where ever you need to.

It can act as a ribbon. It can also act as a single fiber giving you a lot of freedom to use either platform in a much smaller package.

So overall, we think we’re going to see a lot more customers move towards Rollable Ribbon in their fiber to the home distribution networks. And now in the future.

And that’s what’s new in my world today.

When you need a fiber-dense yet compact cabling solution for high-bandwidth, high-density applications, look to the

When you need a fiber-dense yet compact cabling solution for high-bandwidth, high-density applications, look to the